Now 1 very important fact you missed is that in hot sunny conditions a thin film a si module will produce 1 300kwh kwp while a crystalline module will only give 900kwh kwp kwh kilowatt hour.

Silicon vs thin film weight solar panel.

Panels that are made from monocrystalline solar cells are basically fashioned from silicon ingots that have a distinct tube like shape.

Thin film solar pv was hailed as the next big thing in solar nearly a decade ago.

These solar cells are also known as single crystalline silicon because they have a very even and uniform look and this is mainly because only the purest silicon of the highest quality is used to make them.

Abundant and efficient crystalline silicon solar cells have been around since the 1950s but thin film solar cells are the new kids set to become the medium of choice.

Then crystalline silicon wafer c si cells occupied more than 80 of the market share compared to thin film pv 1.

Unisolar is only 1 manufacturer and an expensive one.

From this melt a rod is then drawn which forms a uniform crystal lattice a so called single crystal or monocrystal.

Crystalline solar panel cells are made from the basic material silicon in contrast to thin film or dye cells.

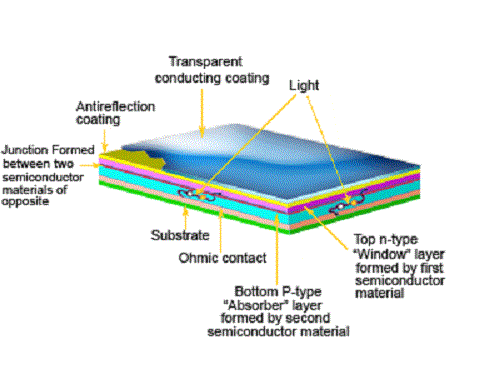

Thin film is a type of solar cell where the photovoltaic material is essentially printed onto a surface.

Thin film cells can be bent and even.

There was a high anticipation in the industry for thin film pv to position itself for a run at c si and dominate the market for the near future.