Side milling definition is the process of milling surfaces that are at right angles to the axis of rotation of the cutter with a side milling cutter.

Side milling cutter definition.

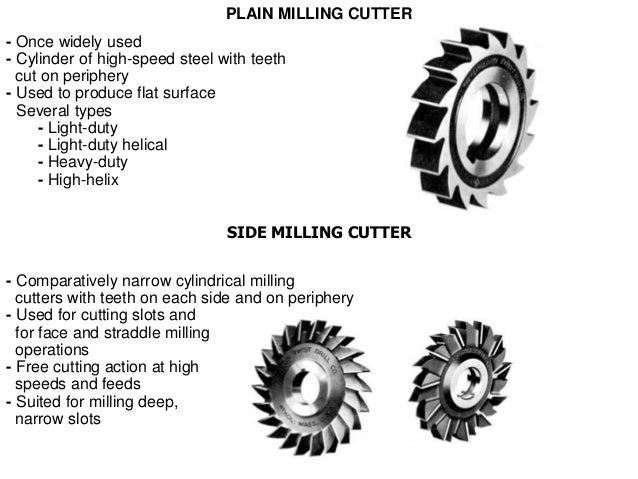

Plain milling cutter s shape is like disc or cylindrical which has blades on the outer circumference of the cutter for milling.

They are available with straight and staggered tooth configurations.

Several standard shapes of milling cutter are used in industry today which are explained in more detail below.

A critical factor in peripheral milling using side and face milling cutters is achieving a suitable feed per tooth f z.

Plain milling cutter is the most commonly used tool in a horizontal milling machine.

This may be done varying direction on one or several axes cutter head speed and pressure.

Calculating feed per tooth.

Choose from our selection of end mills and milling cutters arbor mount milling cutters end mill and milling cutter sets and more.

Milling open slots using side and face milling cutters.

There is also a choice of coatings as well as rake angle and number of cutting surfaces.

In stock and ready to ship.

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a work piece.

Characteristics and processing differences of the four kinds of cutting tools.

Plain milling cutter end mill side milling cutter and face milling cutter plain milling cutter.

Milling covers a wide variety of different operations and machines on scales from small individual parts to large heavy duty gang milling operations.

Side milling cutter definition is a cylindrical milling cutter with teeth on the circumferential surface and on both sides.

Insufficient values cause serious disadvantages so that extra care should always be taken when calculating this.